Industrial vibration sensor technology is one of the primary methods of enabling machine health monitoring and predictive maintenance for industrial equipment. Machine vibration sensors use an accelerometer to measure and transmit data about the vibration of rotating equipment. Even the smallest deviations are detected from normalized benchmarks.

The discrepancies that machine vibration monitoring can discover are often an early sign of equipment malfunctions — the type that will eventually lead to machinery shutdown, unplanned downtime and increased wear on moving parts. With a machine vibration monitoring system in place, maintenance teams can monitor performance and detect potential issues well before they lead to costly downtime and equipment damage.

How do vibration sensors work?

Industrial vibration sensors utilize a variety of technologies to detect vibrations in equipment. For example, accelerometers measure the amount of motion within a machine and transmit that information to measurement instruments. There, advanced software translates the signals received and produces highly accurate readouts of the intensity and frequency of the vibration. Although accelerometer-based vibration detection devices are the most popular, they are not the only type available. Other types include strain gauges, which use sensors that convert force or pressure into electrical resistance. Capacitive displacement vibration analysis sensors feature magnetic components that allow for non-contact measurement.

Where to use vibration sensors

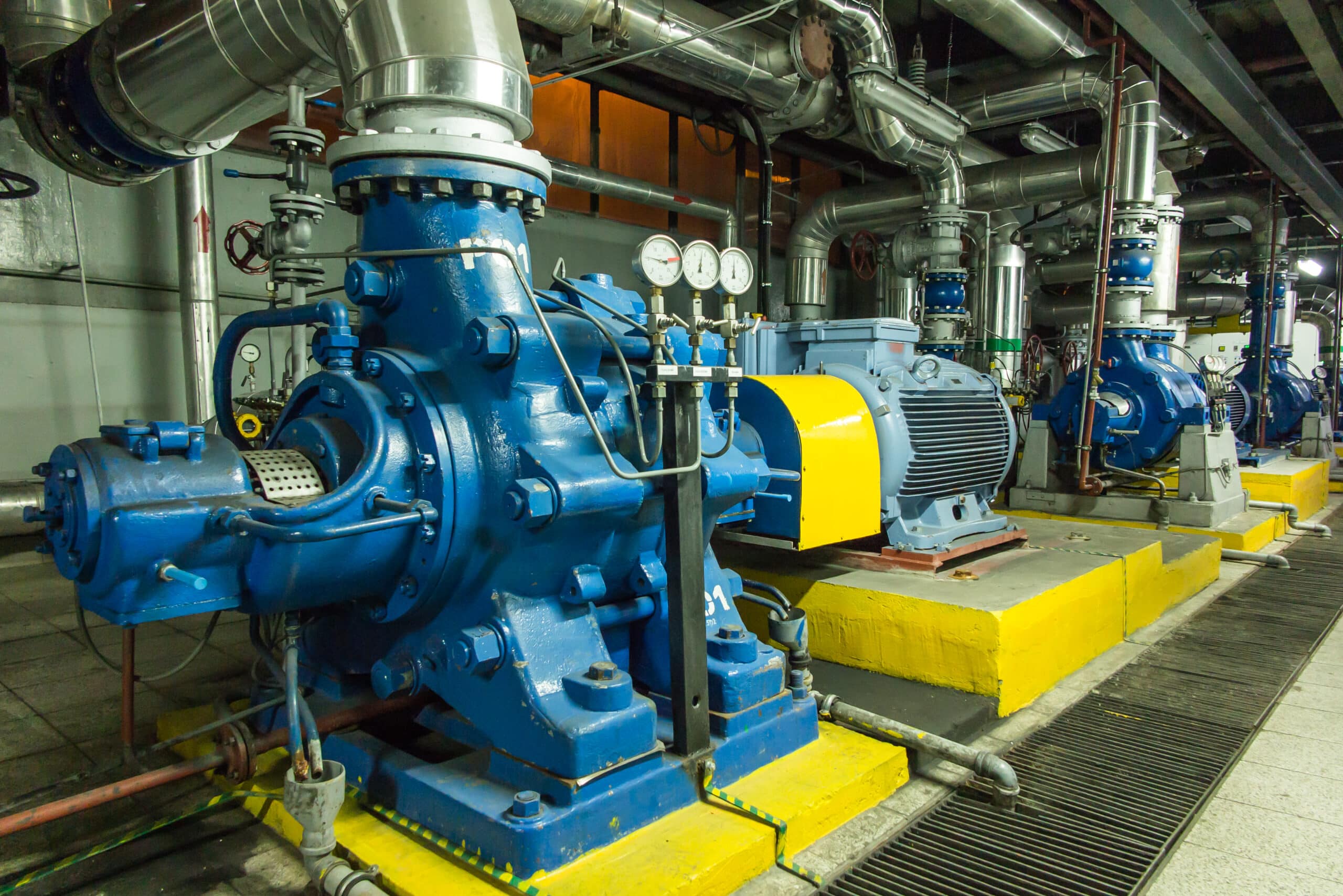

Vibration sensors are useful on any type of moving equipment, particularly any type of rotating equipment where increased vibration is likely to be an indicator of impending malfunction.

Types of equipment where vibration sensors can be useful are:

- Motors

- Pumps

- Compressors

- Fans

- Blowers

- Bearings

- Gearboxes

- And more

The benefits of vibration analysis

Predict and prevent machine failures

Data shows that vibration discrepancies from the norm are a reliable indicator of impending equipment malfunction and failure. When rotating equipment begins to operate out of spec, with increased vibration, it is a sign that a component might be damaged; may be under- or overlubricated; that foreign particles could be present; or that components may be failing before expected.

When these issues are starting, they can be difficult to detect — in contrast to the point when they lead to equipment shutdown and potential damage, when they can be clearly heard and noticed. The power of vibration sensors lies in the ability to detect these aberrations early, well before they create bigger problems.

Prevent unplanned downtime

Vibration sensors allow maintenance technicians to be notified of potential problems essentially at the moment they start — which can be hours before an equipment shutdown scenario. This allows maintenance teams to diagnose the problem and make a proactive decision — potentially even finishing a production cycle — before taking steps to remedy the problem. This proactive approach allows for more effective maintenance scheduling, all but eliminating the reactive approach that leads to unplanned downtime, missed deadlines, rush work and production costs that spiral out of control.

Industries served

Flexible technology for multiple industries

These sensors are utilized in a wide range of industrial applications, including the monitoring conduits, motors and conveyors. This means these devices often need to be calibrated and customized to meet the specific needs of a particular industry.

Maintaining the flexibility to meet specific company and industry needs, we focus on eight core areas of manufacturing. We are also always ready to innovate and develop custom plans for customers outside these areas — with the experience and expertise to apply our solutions wherever they are needed.

- Aerospace

- Automotive

- Building Products

- Consumer Packaged Goods

- Heavy Equipment

- Paper & Pulp

- Power Distribution

- Tire and Rubber

Gaining a competitive edge

At ATS, we’ve developed our predictive maintenance solutions to maximize the value and return on investment for you. Drawing on decades of experience in industrial technology, we know what works and what doesn’t. Our goal is to implement a solution that lets you get up and running as quickly as possible to make an immediate difference in your equipment reliability.

Protect against downtime

Are you looking for a data-driven maintenance program that gives you the insight and analytics to be proactive against downtime?

ATS can help! Contact us.