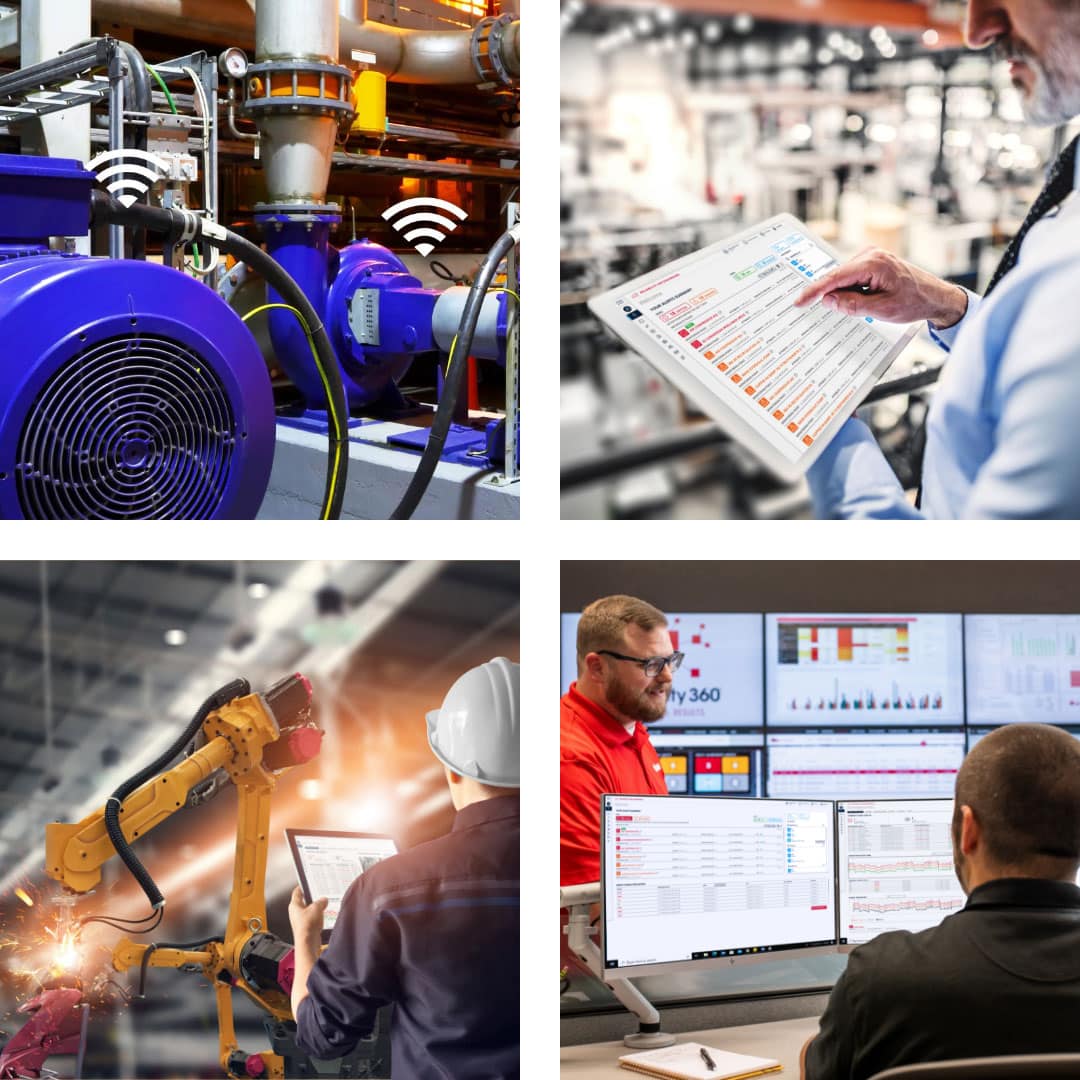

Enabling data analytics and machine insights

Maintenance sensors collect machine performance data and transmit it using Ethernet or cellular service to a cloud-based system for analysis. By detecting asset health fluctuations, these sensors enable early intervention, reducing downtime, improving efficiency, and supporting data-driven maintenance strategies. Secure network integration ensures that the data is transmitted safely and reliably, protecting sensitive information and enhancing overall system security.

A robust condition monitoring program starts with the right sensor. Our selection of sensors covers a wide range of monitoring needs and is applicable to several types of equipment throughout the factory floor.

Our monitoring capabilities

Vibration

With several configuration and form factors to suit various applications, our vibration sensors provide full spectral vibration and temperature monitoring for your critical rotating equipment. With sensing ranges up to +/- 16g and 25.6kHZ, and an optional Class 1 Div. 2 enclosure rating, our sensors combined with our Reliability 360® Machine Health Monitoring platform and analytics provide the data, insights and results needed to confidently utilize vibration as the cornerstone of industrial predictive maintenance.

Ultrasonic

Applicable for low-speed rotating equipment and as stand-alone bearing fault detection, our industry leading high-resolution ultrasonic sensors are an exceptional match to compliment any predictive maintenance program. With a variety of ultrasonic sensor configurations and an optional Class 1 Div. 2 rating enclosure, combined with our Reliability 360® Machine Health Monitoring platform and analytics, you can trust that defects in critical assets can be identified and acted upon with advanced notice.

Temperature

Temperature is a critical attribute of interest in providing contextual evidence of component conditions and imminent failure modes. We employ a wide variety of temperature monitoring capabilities within our vibration sensors, environmental sensors or as a stand-alone solution. Combined with our Reliability 360® Machine Health Monitoring platform and analytics, temperature data can be used contextually, comparatively or independently for an additional layer of confidence when diagnosing equipment conditions.

Electrical current

Electrical current draw serves as a primary contextual data point to determine changes in load on monitored equipment and serves to determine electrical health through comparative analysis between electrical phases and redundant equipment. With capabilities from 0-1000 amps, an optional Class 1 Div. 2 enclosure and additional advanced options, these sensors are an exceptional match for both predictive maintenance programs and sustainability initiatives. When combined with our Reliability 360® Machine Health Monitoring platform and analytics, analysts gain important insights about equipment health, operation and load variations to address changing conditions and diagnose potential failure modes.

Pressure

Whether monitoring pressure on vessels and tanks, or line pressure as a process or equipment health variable, our absolute and gauge pressure sensors are equipped for your liquid, gas or vapor data collection needs from 0-5000psi anywhere a common ¼” NPT port is available. Combined with our Reliability 360® Machine Health Monitoring platform and analytics, pressure data can be used contextually, comparatively or independently for an additional layer of confidence when diagnosing equipment conditions.

Flow

Compatible with a variety of pipe materials and liquids, our flow sensors can detect the flow rate of a liquid without any pipe modification needed. This device enables the detection of a wide variety of liquids, including water (and pure water), oil and chemicals. Detection is possible on both metal and resin pipes measuring 1″ to 1 ¼” in diameter. Unlike conventional flow sensors, installation and operation are easy on high-pressure pipes. Combined with our Reliability 360® Machine Health Monitoring platform and analytics, flow rate data can be used contextually, comparatively or independently for an additional layer of confidence when diagnosing equipment conditions.

Environmental conditions

Our environmental air quality sensor monitors temperature, pressure, humidity, gas resistance and indoor air quality. With several applications including long endurance industrial automation, home automation and control, indoor air quality monitoring and component of IoT HVAC system, this sensor can provide invaluable insights across your facility.

Environmental Air & Quality Sensor >

What sets ATS apart?

Unlike other maintenance sensor providers, Reliability 360® Machine Health Monitoring goes beyond the sensor hardware. Our end-to-end IIoT solution includes consultation and installation services to ensure you monitor the right assets and collect the right data for your business goals. Additionally, we provide expert analysis and prescriptive actions to effectively resolve alerts as they occur.

Make your factory run better & smarter

Predictive maintenance sensor resources

Learn best practices and how sensors can benefit your maintenance strategy.

Condition monitoring for manufacturers

Our machine health monitoring solution delivers measurable results across process and discrete manufacturing and provides increased efficiencies for functions throughout the organization.