Our part repair services include

One provider for all things MRO

Consolidate suppliers, reduce procurement effort and streamline communications through our industrial repair services.

Increased cost savings

Our part repair process is geared towards finding the most cost-effective solution, whether that be repairing your part or sourcing a replacement part.

Optimized maintenance efficiency

We provide detailed reporting and a best-in-class warranty with every industrial equipment repair to drive asset reliability.

Get the right part at the right time

Older electronic and mechanical parts always seem to fail at the worst time, postponing production and complicating maintenance work orders. Our experienced approach to industrial machine repair provides our customers with a fast, quality solution at a significant cost savings—allowing them to spend less time fixing broken equipment and more time meeting production demands.

Surplus, refurbished, new and repaired parts offer manufacturers multiple MRO parts solutions—all through one provider. Our detailed industrial repair services deliver comprehensive cleaning and inspection before repair and provide full functional testing after repair—ensuring your returned part is ready to run with a warranty guarantee. Highly skilled ATS technicians provide quality repairs with a quick turnaround saving manufacturers up to 40-60% by repairing their part vs. buying new.

-

160+ supplier partnerships

-

1,000+ OEM brands serviced

-

60,000+ part SKUs

-

2X ROI in cost savings

-

200% extended product operating life

We repair the parts that matter most to you

Backed by 40 years of experience, we deliver high-quality repairs for more than 1,000 OEM brands, ensuring your equipment performs at its best.

Minimize downtime with expert parts repair services.

Cut costs through a proven reliability-focused approach.

Prevent failures by addressing recurring issues effectively.

Industrial controls

Full system testing for PLCs, CNCs, robotics and more to ensure reliability and functionality.

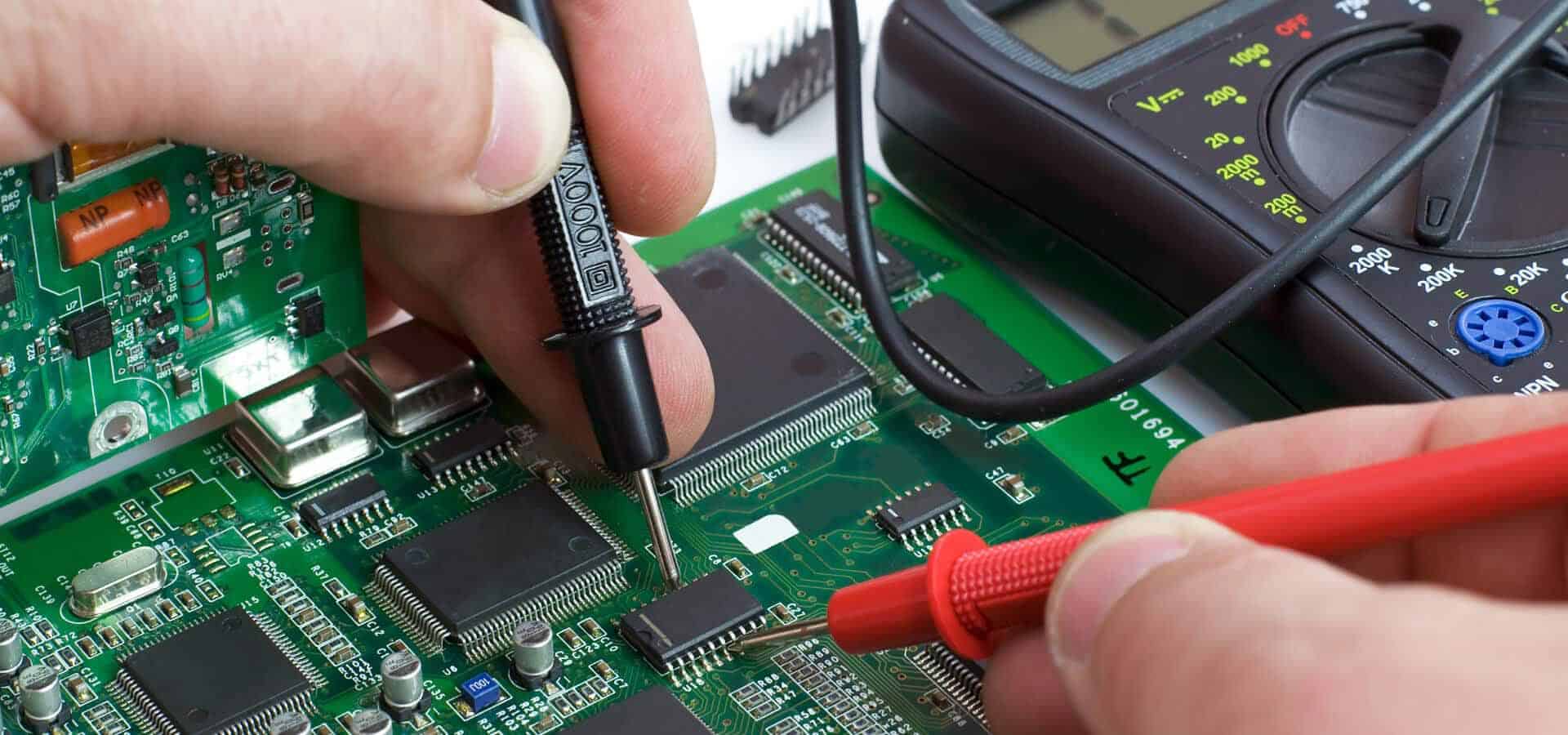

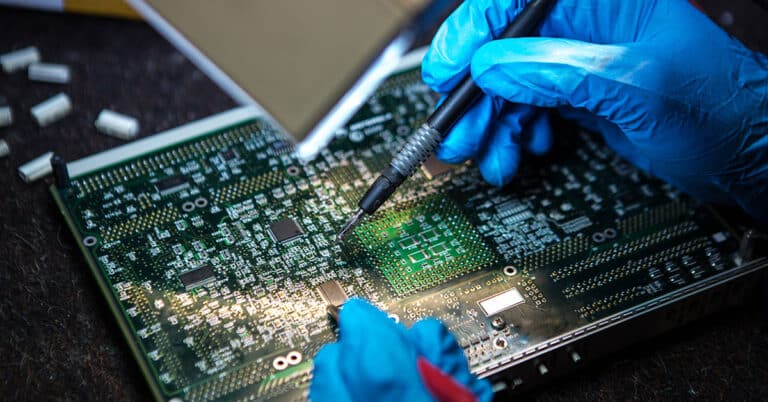

Electronics

Ensure optimal functionality through load testing, light curtain tests and advanced circuit testing.

Position controls

Test and load drives up to 500 horsepower, secure functionality and precise feedback signals.

Plant automation

Repair hardware/software while exceeding OEM standards and retrofit obsolete components with new technology.

Mechanical

OEM parts, precise machining, coatings and rigorous testing deliver best-in-class refurbishments.

Power train/motion

EASA-certified services include rewinds, repairs, inspections and testing with OEM parts, ensuring alignment and verified functionality.

Electro-mechanical

Free evaluation, precise machining and testing to ensure fully functional electro-mechanical refurbishments.

Top OEMs we support

Virtual tour: ATS service center

Take a peek inside our state-of-the-art service center to learn more about our approach and extensive best-in-class part repair process.

Need a part repaired?

Explore industrial equipment repair & MRO resources

Learn about parts repair, MRO best practices and the latest industrial machine maintenance insights from ATS thought leaders and industry experts.

Brochure

Industrial machine repair services for manufacturers

Our industrial machinery repair services and fully stocked industrial parts store deliver cost-effective options for repair, surplus or new parts across process and discrete manufacturing, streamlining operational functions across organizations.