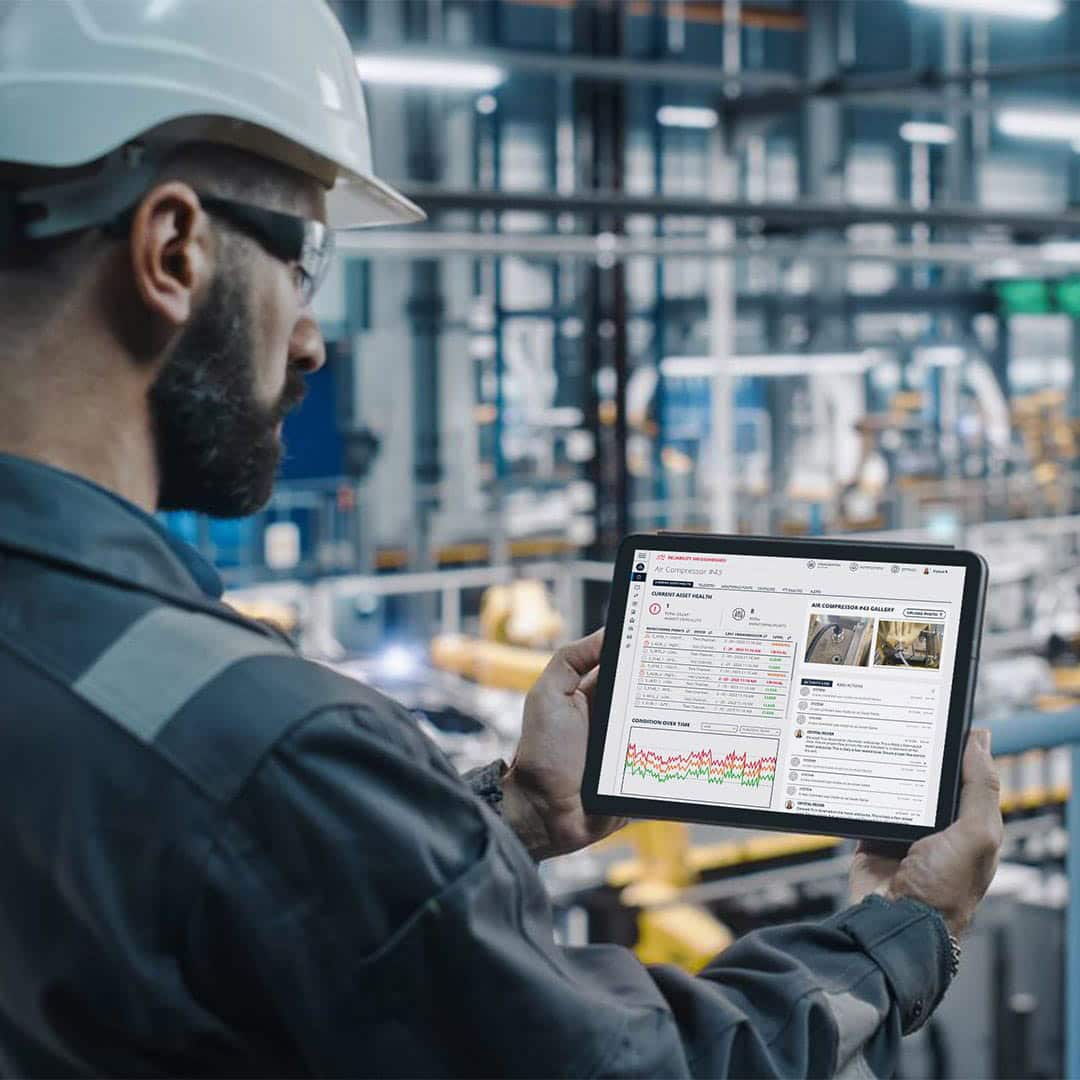

Reliability expertise at your fingertips

Reliability engineering

Utilizing our many technologies and standard processes we help you evolve from a reactive to proactive state of best-in-class maintenance.

Maintenance forum

Specialists in maintenance and reliability provide answers and corrective actions or refer the query to a subject matter expert.

Subject matter experts

Experts in remote troubleshooting and diagnostics of complex maintenance issues providing real-time corrective actions.

Technician hub

Online resource hub for field technicians including OEM manuals, troubleshooting guides and best practices.

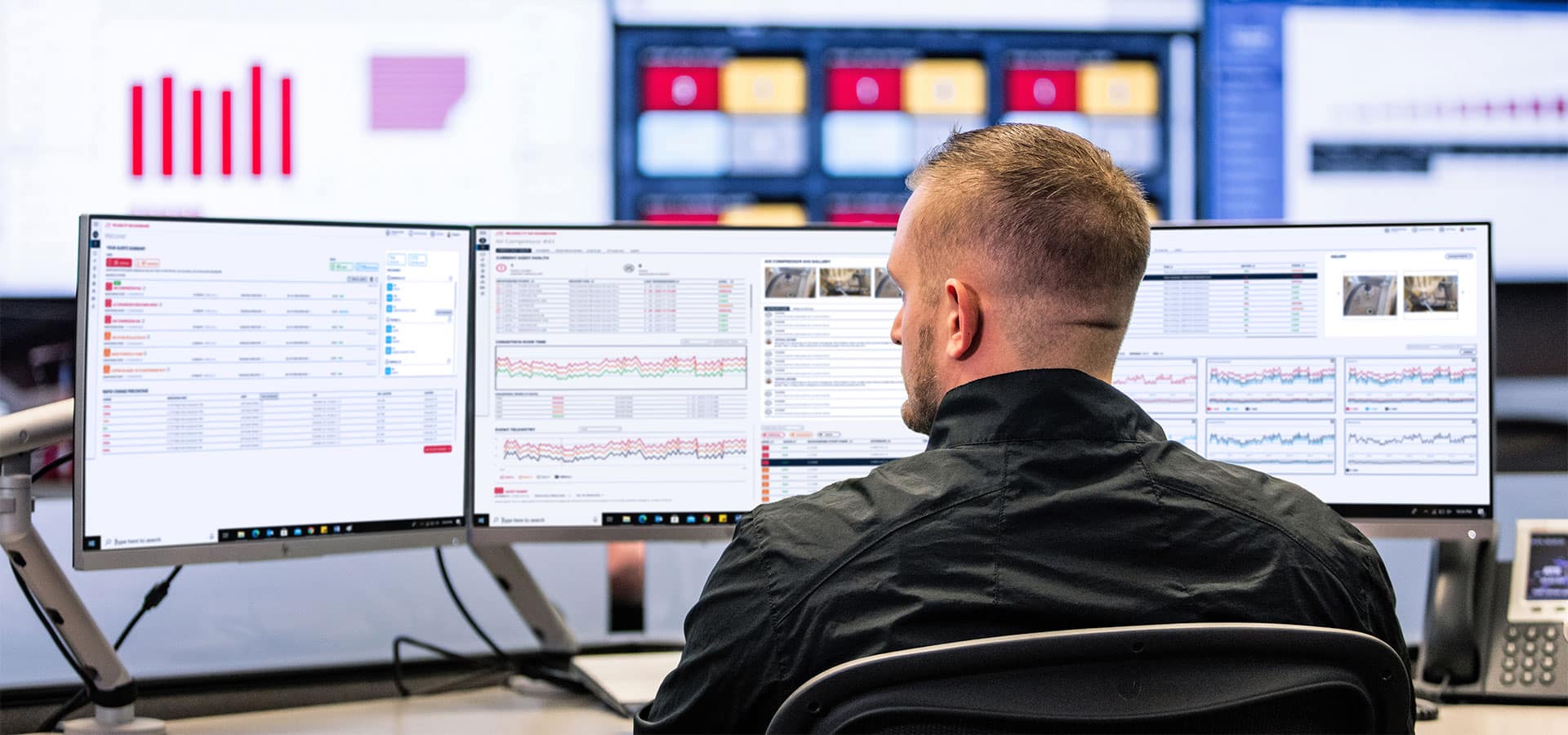

From your machines to our technology center

Within a smarter factory, machine data and insights drive productivity and enable a more predictive, reliability-centered maintenance program.

Our R360® Technology Center is designed around Industrial IoT, remote maintenance monitoring and sensor technologies drawing data from connected devices on your equipment. This real-time asset monitoring notifies our condition monitoring experts of potential machine health issues, before affecting production and causing unplanned downtime – delivering increased uptime and avoided losses.

Monitoring and analyzing data in one centralized location through remote machine monitoring and targeted projects, provides the key metrics and actionable insights necessary to improve technician and production efficiency.

Tap into reliability experts

Don’t miss the chance to explore, learn and be inspired by the maintenance and reliability excellence our predictive technology solution and support can drive at your manufacturing plant.

What sets ATS apart?

With four decades of industrial reliability and maintenance experience, manufacturers trust ATS to increase uptime, improve asset performance, drive enterprise scalability and enable predictive maintenance processes – all driven by our R360® Technology Center.

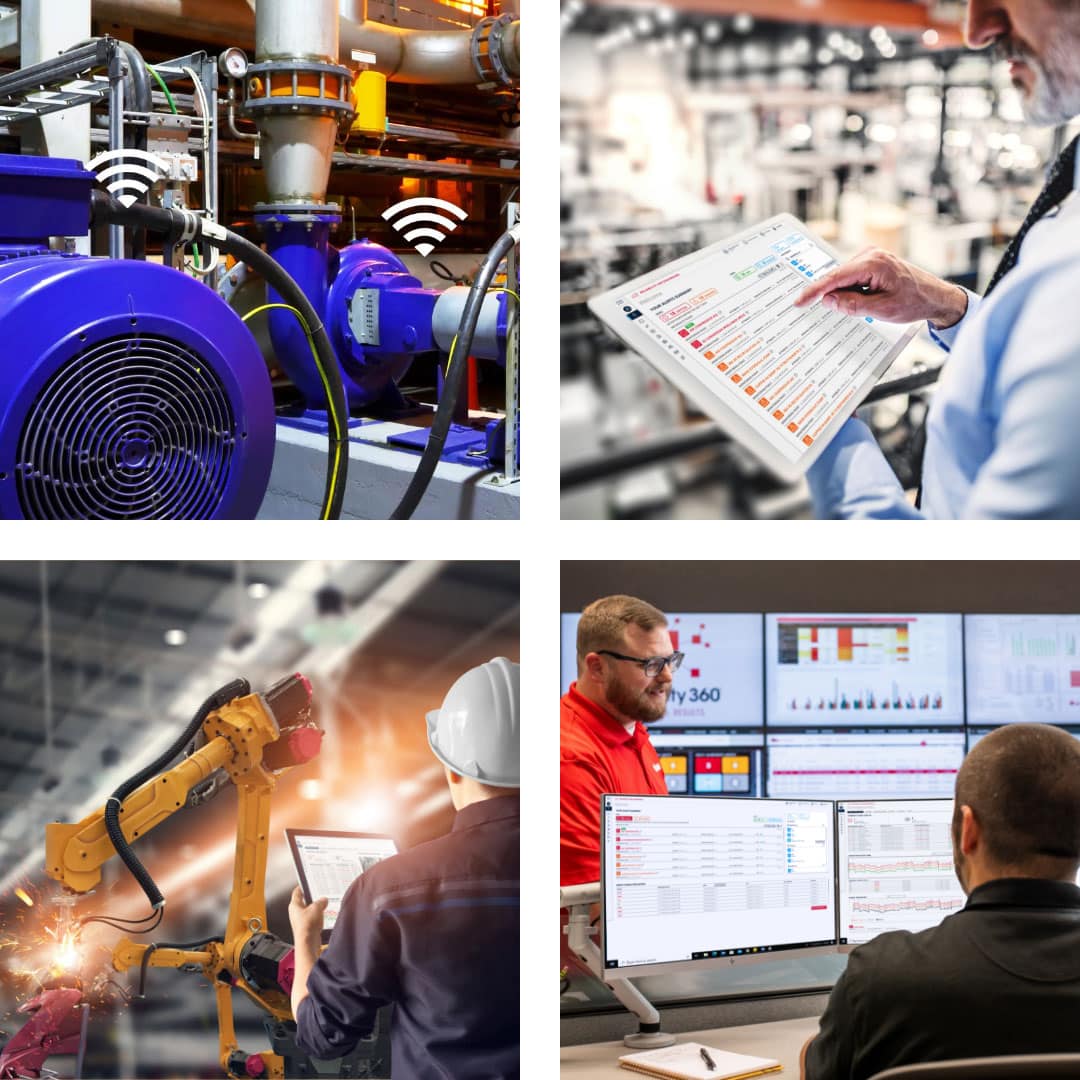

End-to-end IIoT solution

We leverage four decades of maintenance and reliability experience paired with our remote maintenance monitoring system to prevent unplanned downtime.

- Consultation & installation

- 24/7 condition monitoring

- Real-time alerts

- Prescriptive actions

- Measurable results

- Optional maintenance & parts support

Turnkey comprehensive program

With our comprehensive maintenance solution, manufacturers benefit from a long-term partnership that includes strategy, leadership, technology, multi-craft technicians, training and parts management.

- Increase machine availability, uptime and throughput

- Reduce maintenance labor and material costs

- Minimize total cost of ownership

Turn insights into action

Our Director of Industrial Technologies discusses best practices in data analytics that drive maintenance maturity and shares insights into the strategic benefits of condition monitoring in this 6-page eBook.

“The core value of machine condition monitoring is twofold: (1) drive best practices in reliability and maintenance; and (2) mitigate the skills gap now and into the future.”

Make your factory run better & smarter

Explore resources on industrial technology

Case Study Infographic

Remote monitoring and maintenance solutions for manufacturers

Our decades of experience and best-in-class remote maintenance services deliver measurable results across process and discrete manufacturing, optimizing business functions across organizations.