We understand manufacturing and plant engineering challenges

While every manufacturing business is built on strong manufacturing fundamentals, the ongoing effort to be proactive and manage growth, improve systems, adopt new technology, and retain a competitive edge is often tasked to engineering and can often prove challenging to meet expectations. This can be compounded by issues such as integrating legacy equipment with new process systems and working with limited technical staff.

As a leader in industrial maintenance engineering and technology for over four decades, our core is focused on reliability. We drive reliability-centered maintenance through a team of subject matter experts and technicians optimizing uptime and implementing predictive technology with data analytics support.

Implement predictive maintenance

Increase availability, uptime and OEE

Adopt, deploy and scale new technology

Boost asset reliability, data sharing and ROI

Innovation meets industrial engineering expertise

As industrial technology is proven to increase manufacturing productivity, organizations are forced to re-evaluate their current processes. In order to remain competitive, industrial engineers must direct long-term strategy, develop more proactive maintenance practices and focus on continuously improving uptime and reliability.

Data and technology are the key drivers of these efforts, with the potential to vastly improve uptime, reduce maintenance incidents, control costs, and increase asset performance metrics. We support industrial projects that improve throughput as well as implement predictive technology to reduce downtime. Our industrial engineering solutions give engineers the opportunity to enhance key areas of improvement that can pay significant dividends in industrial plants, including:

-

System integration

Our expertise in integrating new systems with existing processes means greater efficiency and a much stronger overall process.

-

Automation solutions

We work closely with manufacturers to implement the latest automation technology so they can cut down on labor costs and improve the accuracy of what they do.

-

Industrial Internet of Things (IIoT)

The experience we have with IIoT means we can connect machinery to provide real-time insights to guide your decision-making process with greater efficacy.

Report tangible, measurable reliability and performance improvements with proven ROI

Drive performance improvements

As your maintenance and technology partner, we work with you to identify your goals, challenges and opportunities. Our team works hard to align our KPIs with your manufacturing engineering performance targets to ensure we’re providing measurable results for you. We deliver manufacturing and industrial engineering solutions with reliability, expertise and support to help you overcome challenges and meet performance goals.

“Our engineers and ATS work seamlessly together as one team to meet production demands with limited downtime.”

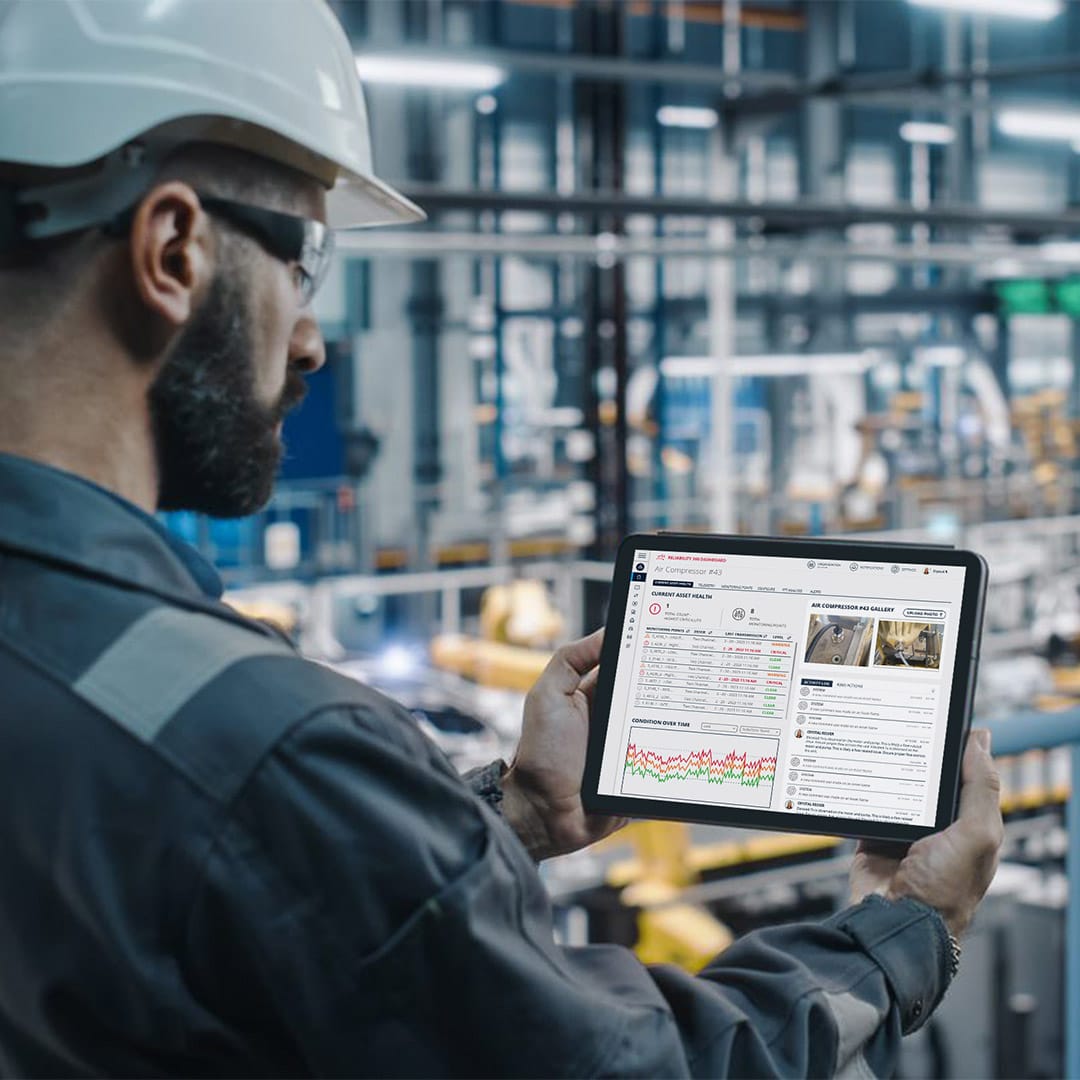

End-to-end IIoT solution

We leverage four decades of maintenance and reliability experience paired with the latest predictive maintenance technologies to prevent unplanned downtime with exceptional deployment speed and easy scalability across your enterprise.

- Consultation & installation

- 24/7 condition monitoring

- Real-time alerts

- Data visualization and dashboards for engineers

- Prescriptive actions

- Measurable results

- Optional maintenance & parts support

Safety excellence starts with ATS

At ATS, we prioritize safety excellence as a key strategy for reducing your downtime, costs and incident rates. Our maintenance technicians work with your teams to implement processes and procedures, reducing incidents and improving employee well-being.

-

World-class safety

Our Beyond Zero safety culture prioritizes compliance and employee well-being

-

Low incident rates

ATS has a 50% lower recordable incident rate than industry average

-

Exceed OSHA standards

ATS has an industry-leading OSHA incident rate and regulatory compliance

Winning together

We pride ourselves in the quality service and measurable results we deliver to our customers. Discover how we can help resolve your unique engineering challenges by partnering together.

Maintenance and engineering solutions for maintenance improvements

Our range of manufacturing and industrial engineering solutions allows us to tailor the right partnership plan to you. From predictive maintenance technology to the strategic use of data, ATS has the tailored solutions needed to bridge the gaps between your operations, engineering and leadership.