Maintenance affects more than just machine availability. It also has a bearing on first pass yield (FPY). What is first pass yield? An important productivity metric, FPY highlights wasteful production and can be an important stimulus for improvement efforts.

The purpose of this blog is to let the maintenance department know how they can influence FPY and why they should seek out opportunities to do that. It starts by explaining what first pass yield is and how it’s calculated before moving on to the value of measuring FPY and then suggesting ways to make improvements.

First pass yield formula

First pass yield refers to the number of good quality parts that come off a machine or production line. In this context “good quality” refers to them being acceptable to the customer, which may be a higher standard than simply meeting the specification.

First pass yield is calculated as a percentage of the total number of parts produced; the formula is:

FPY = [(Number of saleable parts produced) / (Total number of parts produced over that time period)] x 100

Readers familiar with the Overall Equipment Effectiveness (OEE) calculation will notice the similarity with the quality score component. In OEE quality performance is expressed in time whereas the FPY calculation uses number of units, but given a fixed part production rate, these two are interchangeable.

First pass yield example

Working through the formula with numbers from a hypothetical manufacturing process will illustrate how it should be used.

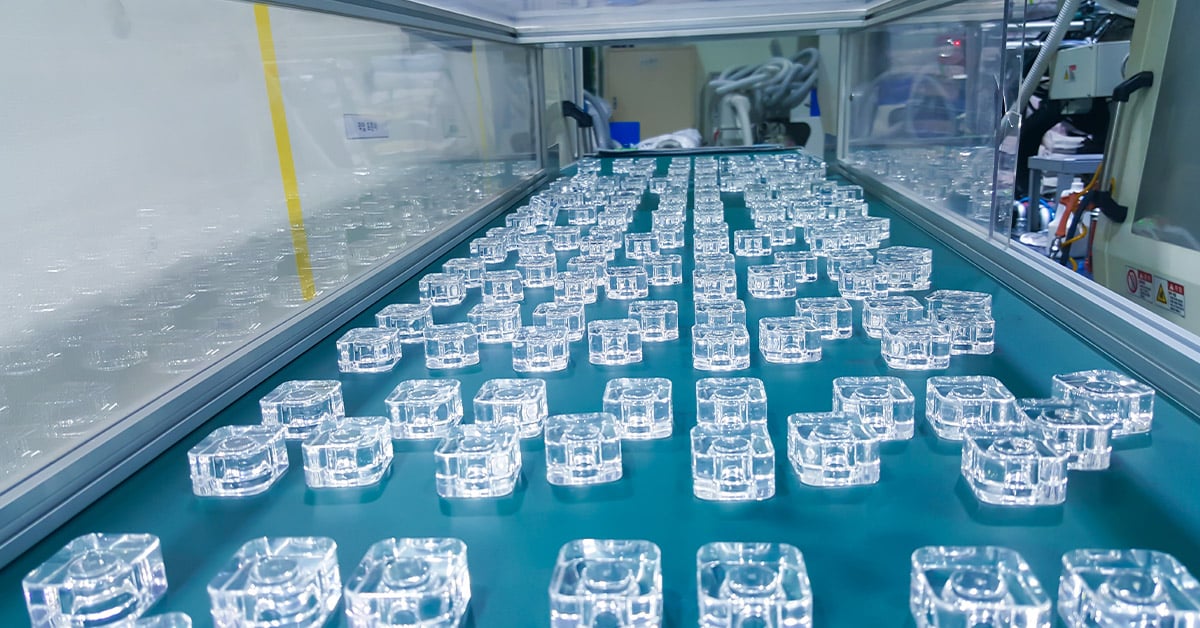

Consider a molding machine that ejects 10 plastic parts per cycle and runs at 10 cycles per hour. In a full hour it will produce 100 parts.

These are then weighed to check for sufficient material and 5 are found underweight. Then the number of parts meeting specification is 95.

Visual inspection subsequently discovers 3 parts are coated with mold release. They can be cleaned and sold, but this needs more work. Therefore, these parts are not of saleable quality direct from the machine.

In this example, FPY = [(100- (5+3))/100] x 100 = 92%

Benefits of measuring first pass yield

FPY shows the proportion of product being wasted due to quality problems. This is a significant productivity issue because:

- Nonconforming product must be reviewed and a decision made whether to rework or scrap.

- Rework is expensive.

- Scrapping the products means material and machine capacity were wasted.

- If scrap products can’t be recycled (castings for example can be remelted and the alloy used again), disposal may carry additional costs.

Reporting FPY frequently, perhaps via a dashboard, shows whether quality levels are constant, falling, or hopefully rising. A declining metric should prompt some investigation as to the cause. An improvement will show that corrective actions have been effective.

How to improve first pass yield

The start point is to analyze the reasons for product not being of saleable quality straight from the machine. Typically, these will be presented in the form of a pareto chart, letting management focus on the biggest issues.

Processing yield problems generally fall into one of the following four types:

- Defective material: If raw material varies in composition, perhaps as a result of coming from a different supplier, it may process differently and so achieve different results. For example, it may have a different curing behavior or glass transition temperature.

- Workers deviating from Standard Operating Procedures (SOPs): Changing the assembly sequence or using the wrong tool could result in a product not performing as designed. An example would be using a fastening tool set to the wrong torque, or not torquing a fastener at all.

- Damaged, worn or dirty tools: For example, chipped cutting tools and dirty molds give rise to dimensional errors and poor surface finishes.

- Excessive variation in the process: Wear in guides, bushings and other machine parts can lead to misplacement of holes or labels. Fill quantities might vary more than they should, appearance can suffer and functionality might be reduced.

While material problems and failures to follow SOPs (or the absence of SOPs), should be addressed by Purchasing, Quality and Operations management, many of the machine-related problems fall within the maintenance sphere.

The maintenance function should implement a planned maintenance program to detect and correct for wear in machine parts. This could be done on a time basis, although a more effective approach is to implement some form of machine health monitoring. This flags deviations from normal operation to the CMMS or the maintenance planning team so replacement parts can be ordered and corrective actions scheduled for when they are least disruptive.

Address FPY in manufacturing

First pass yield is an important, though sometimes overlooked, performance metric. It indicates the proportion of production time and materials that are being wasted making parts that can’t be sold.

Analyzing the reasons for a poor or declining FPY will reveal opportunities for improvement. Multiple functions will be involved in addressing these, including Maintenance. As a leader in outsourced industrial maintenance, ATS works with manufacturers to improve asset utilization and performance. Contact us to learn how we could help raise FPY in your operations.