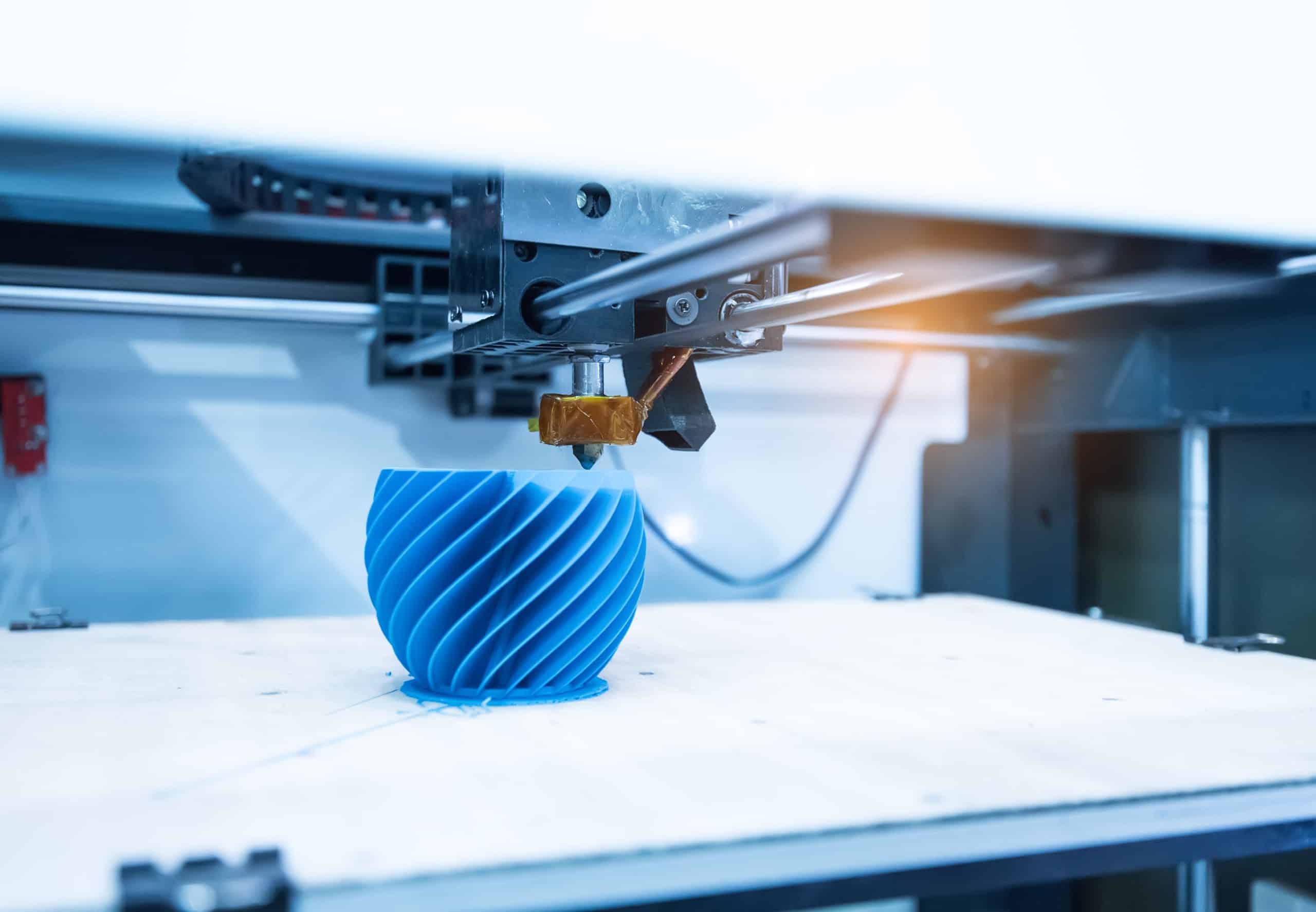

In a number of manufacturing scenarios, 3D-printed parts are already providing highly reliable alternatives to traditional replacement parts.

In the Star Trek television series, one of the many futuristic devices featured was the replicator, an appliance about the size of a microwave oven. It could produce anything on demand — from a dry martini to a bowl of chicken soup. But while that was from a fictional world hundreds of years into the future, nowadays 3D printers are the closest thing we have to a real-life replicator.

The prospects of 3D printed parts

Star Trek foreshadowed a future that is now here. In that universe, the replicator didn’t just serve dinner—it was also used to make spare parts for the ship, so it wouldn’t have to return to base every time a repair was needed. In a similar way, manufacturing plants can use 3D printing to create quality 3D-printed industrial parts for just about any type of equipment in any environment, solving spare parts issues quickly and economically. 3D printing capabilities can be especially important for manufacturers who need difficult-to-find parts and accessories for aging machinery, especially at legacy manufacturing plants.

Many 3D-printed parts outlast alternatives created using more conventional methods, even in rough industrial environments. For example, using a 3D printer, experts can create plastic parts that are enhanced with metals to improve durability under challenging conditions. And as time goes on, 3D printing technology keeps getting more advanced, allowing for more enhancement possibilities and even more 3D printing industrial applications.

Impact on repairable parts management

The 3D printing effect on manufacturing and maintenance has been significant and only continues to grow. While some manufacturers already use 3D printing to create prototypes, industrial operations are increasingly finding that 3D printing applications for efficient spare parts management is essential.

For example, if a company needs a handful of replacement parts but finds that they can only purchase each needed product in bulk, using a 3D printer to create just a small batch can be more cost-effective. One of the other uses of 3D printing in manufacturing is for obsolete parts. It’s not unusual for machine lifecycles to greatly exceed the number of years the equipment manufacturer makes spare parts for it.

A factory might have a 15-year-old machine that the original equipment manufacturer stopped making spare parts for after 10 years. In that scenario, 3D parts manufacturing with a 3D printer can be a lifesaver. 3D printing may still sound futuristic, but it’s already playing a role in manufacturing operations today, producing parts that fold seamlessly into supply chains worldwide. To learn more about 3D printing applications in manufacturing and the ways 3D printing can help your legacy machines, contact us.