A major trend making waves in the automotive industry is the use of additive manufacturing, also known as 3D printing. Like other types of manufacturing technology, additive manufacturing continues to evolve and thus can be used in a wide range of applications and functions. As manufacturers find more uses for additive manufacturing in the automotive sector, they gain numerous benefits as well. Throughout this piece, we will explore those applications and the advantages that they offer.

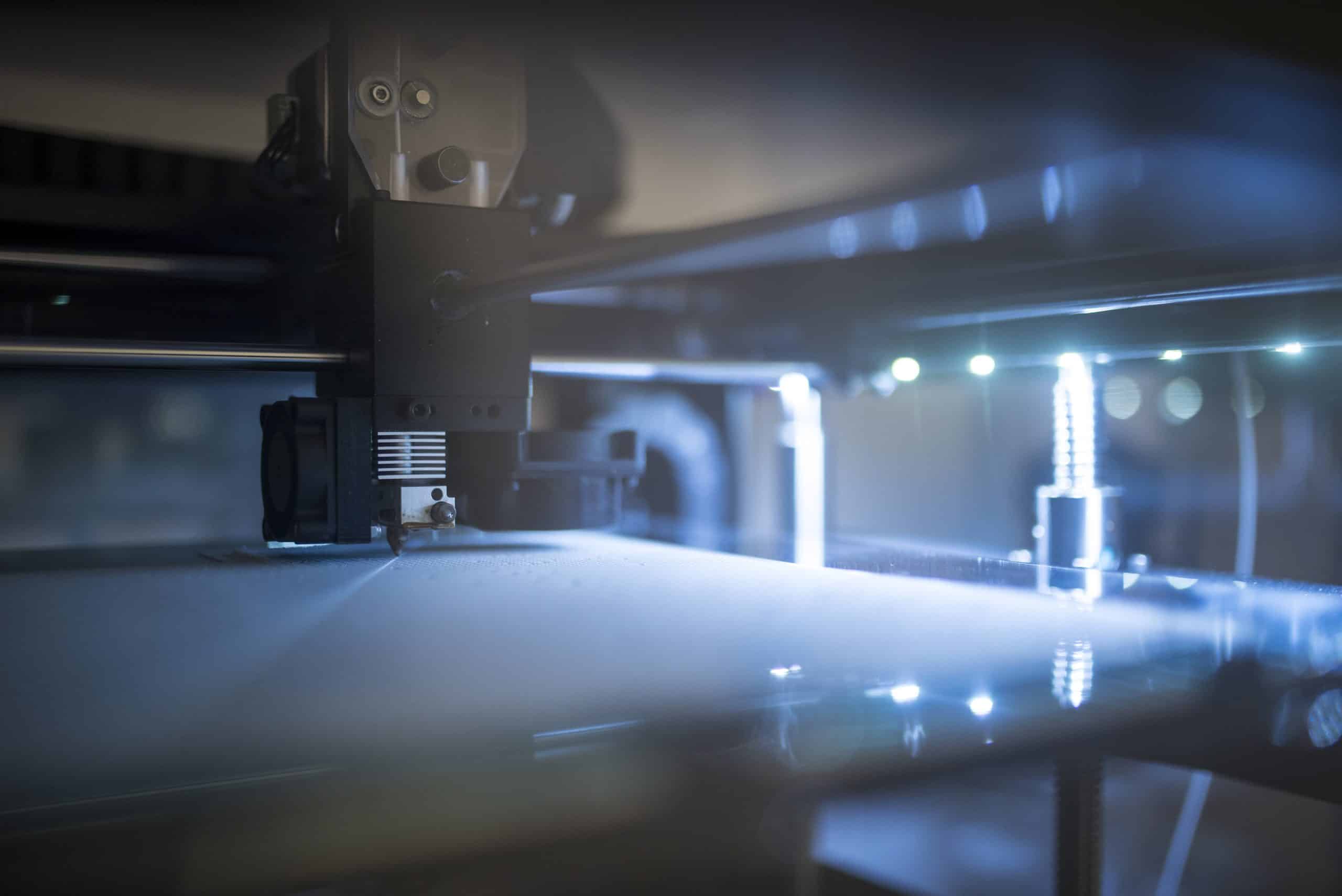

Before that, let’s briefly recap the principles of additive manufacturing. The term “additive manufacturing,” or “3D printing,” actually covers a number of different technologies, such as selective laser sintering (SLS), fused deposition modeling (FDM), and others. The common thread is that these processes “build” a component layer by thin layer, eventually completing the form of the finished part. This is in contrast to subtractive manufacturing (such as machining), where a part is formed by removing material from raw stock.

Additive manufacturing applications in the auto industry

Additive manufacturing for car parts has become more common in recent years. Some applications include:

- Rapid prototyping during R&D: Innovation in the automotive industry is moving faster than ever, with technology such as self-driving cars and electric vehicles leading the charge — even as traditional vehicles remain hot-ticket items among consumers. In the ongoing race to be the first and best, auto manufacturers must continually engage in research and development in order to create better products and get them to market faster than their competitors. Additive manufacturing is a huge help in this process, with its ability to quickly create working prototypes in just a few hours, instead of typical turnarounds of several days or more. This can help product designers test and iterate more frequently and cost-effectively, ultimately leading to better end products.

- Weight reduction: Weight reduction has long been desirable for traditional vehicles as a way of improving fuel efficiency. This concern is more important than ever for electric vehicles, since lower weight can mean vastly longer battery life between charges. As the quality and speed of additive manufacturing continues to improve, more components that were previously manufactured from solid, heavy metal materials can now be produced via additive manufacturing. This makes it easier to create hollow pieces and utilize other weight-reducing tactics while using lighter materials.

- Streamlining customization: Customization is one of the most popular trends in the automotive industry, not only in aftermarket products, but also in factory options for new vehicles. Additive manufacturing makes it easy and cost-effective to create one-off custom parts that would otherwise need to be machined or molded with all of the attendant tooling time and costs. Additive manufacturing tooling for the automotive industry — as well as the direct production of custom parts — helps streamline these processes.

- Manufacturing replacement parts: This is one of the most promising additive manufacturing applications in the automotive field. With 3D printers on hand, maintenance and repair facilities would be able to create virtually any replacement part without needing to keep it in stock or order it to complete a job. This technology could change the face of automotive repairs, increasing speed and lowering costs for both the customer and the service provider.

- AR/VR: Augmented and virtual reality systems represent new opportunities for manufacturers. When combined with additive manufacturing in the automotive industry, virtual and augmented reality in manufacturing give designers and engineers the ability to visualize a part in three dimensions before a physical prototype can be created. This enables them to examine designs for any flaws or inconsistencies before any resources are wasted.

Benefits of additive manufacturing

Specifically for the automotive industry, the benefits of utilizing additive manufacturing include:

- Faster turnaround on prototypes and low-volume parts: Because there is minimal setup and no tooling required, additive manufacturing provides a much faster turnaround time on prototypes and short-run parts than traditional manufacturing. This can help with innovation as well as time to market.

- Less wasted material: Generally speaking, the additive process uses only the material that is needed to create the form of the part. (However, some parts do require supports that are later removed, though these can be reclaimed and comprise a negligible percentage of overall material use.) This is in contrast to subtractive manufacturing, where manufacturers must pay for raw stock from which material is then removed — and which must then be handled and discarded responsibly.

- Lower energy usage: Additive manufacturing is far less energy-intensive than traditional manufacturing processes and can, over time, make an impact on energy costs.

- Less need for inventory: If additive manufacturing is used to create replacement parts and tooling, facilities may require less inventory space and management to keep these items on hand. This can reduce overhead and ongoing resource costs.

- Overall cost savings: All of the above factors can result in cost benefits and reductions, especially over time and when compared to traditional manufacturing, yielding a positive return on investment.

A leader in maintenance for the automotive industry

At ATS, our core services revolve around industrial maintenance and MRO asset management including storeroom management, repairable parts management and supply chain and procurement. Our skilled technical workforce is trained in servicing all types of equipment and technology, including automated machinery. Keeping this equipment operational is essential and a tailored maintenance & MRO program is the best way to help you achieve your productivity objectives. In addition, we can undertake 3D printing of obsolete or hard-to-find machine parts in order to fulfill your productivity goals and keep your trusted equipment up and running. To learn more about our services and expertise, contact us today.