Our repairable parts management includes

Managed repairs

Make sure parts are ready when you need them with data-driven spare parts management for maintenance.

Reduced spend on MRO parts

Get regular price and performance analysis to ensure the most cost-efficient solution thanks to our many supplier relationships.

Fewer equipment failures

Our spare parts inventory management improves part reliability through root cause analysis, part rebuilds, emergency repairs and more.

Cost savings

Reduce replacement part costs by effectively repairing and refurbishing parts rather than paying for brand-new components.

Enhanced equipment lifespan

Each part is repaired with reliability in mind, with the ultimate goal of extending the lifespan of your equipment.

MRO inventory optimization

Ensure critical parts are always available with optimized MRO inventory management that integrates with your ERP system and other data sources to provide accurate forecasting and automated reordering triggers.

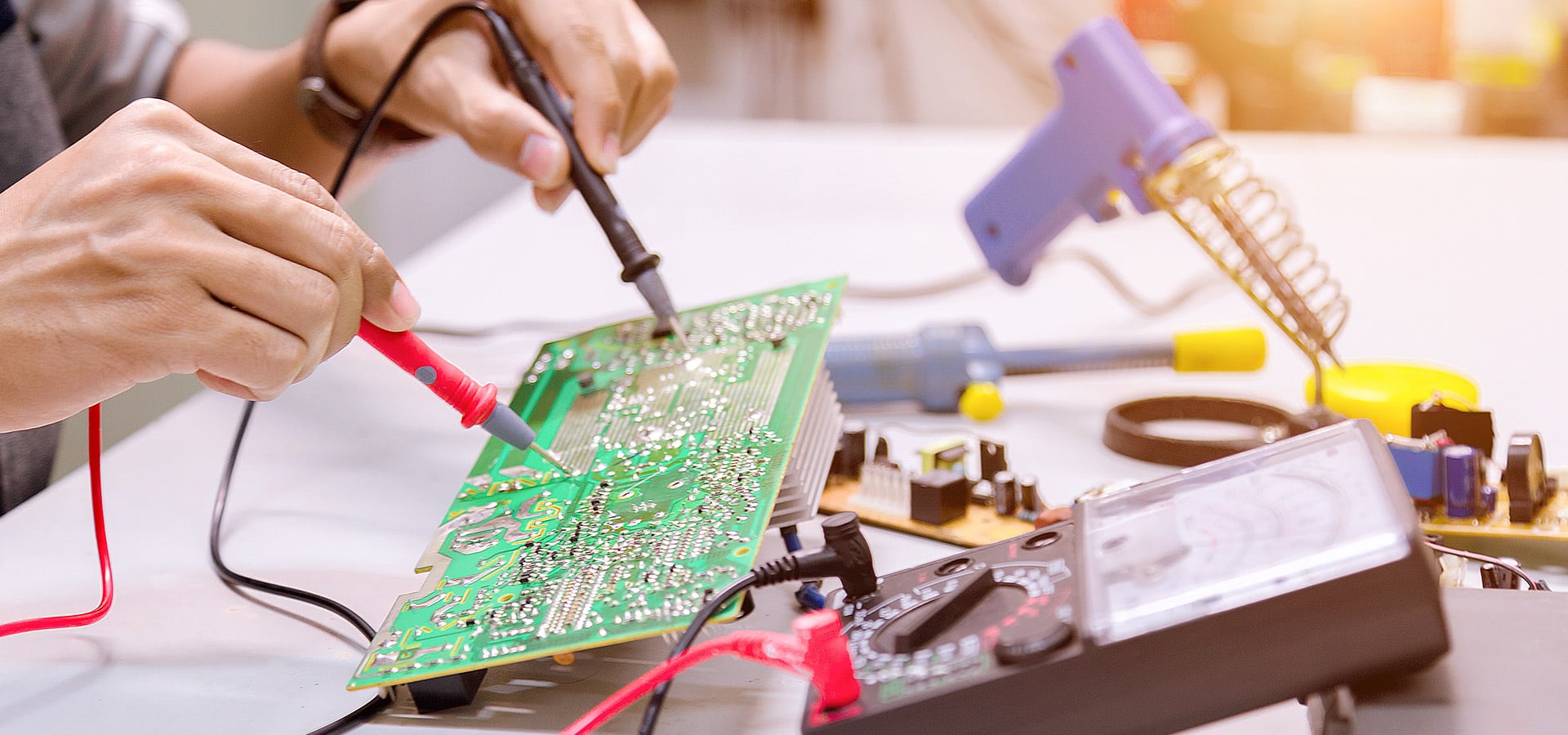

Enhance maintenance efficiency with a repairable parts management program

Part failure is an inevitable aspect of manufacturing; whether it was from faulty design or normal wear and tear, your parts will eventually need attention. Having a proactive plan that addresses the root cause of a failing part can prevent failure from happening in the future—that’s why we provide a data-driven MRO spare parts management program designed to continually improve the reliability of industrial components—and the machines they go into.

The program is managed by ATS through an on-site lead responsible for the end-to-end process execution that focuses on improving part reliability and reducing overall part costs. Through our competitive repair pricing and strategic sourcing for legacy assets, we provide our customers world-class MRO service parts management.

-

160+ supplier partnerships

-

1,000+ OEM brands serviced

-

60,000+ part SKUs

-

2X ROI in cost savings

-

200% extended product operating life

We repair the parts that matter most to you

Backed by 40 years of experience, we deliver high-quality repairs for more than 1,000 OEM brands, ensuring your equipment performs at its best.

- Minimize downtime with expert spare parts repair services

- Cut costs through a proven reliability-focused approach

- Prevent failures by addressing recurring issues effectively

Industrial controls

Full system testing for PLCs, CNCs, robotics and more to ensure reliability and functionality.

Electronics

Ensure optimal functionality through load testing, light curtain tests and advanced circuit testing.

Position controls

Test and load drives up to 500 horsepower, secure functionality and precise feedback signals.

Plant automation

Repair hardware/software while exceeding OEM standards and retrofit obsolete components with new technology.

Mechanical

OEM parts, precise machining, coatings and rigorous testing deliver best-in-class refurbishments.

Power train/motion

EASA-certified services include rewinds, repairs, inspections and testing with OEM parts, ensuring alignment and verified functionality.

Electro-mechanical

Free evaluation, precise machining and testing to ensure fully functional electro-mechanical refurbishments.

Top OEMs we support

Eliminate common MRO challenges

ATS brings together data from your business units and ERP, EAM, or P2P systems and turns that data into actionable insights. We can help you achieve network-wide material visibility, reduce search and order costs, improve service levels and strengthen alignment between operations and procurement.

- Harmonize MRO data across plants, systems and teams

- Optimize existing inventory levels while reducing risk

- Gain visibility to MRO materials across your networks

- Capture team expertise & knowledge

- Proactively address MRO spending reduction opportunities

- Onboard quickly and unlock value within 60 days

- Unify MRO data through CMMS integrations and digital dashboards

Drive cost savings with repairable parts management

Explore MRO spare parts resources

Learn about MRO best practices and the latest spare parts management for maintenance insights from ATS thought leaders and industry experts.

Info Sheet

White Paper

MRO spare parts management for manufacturers

Our MRO management expertise delivers a cost-effective option for repairable parts across process and discrete manufacturing, streamlining operational functions across organizations.